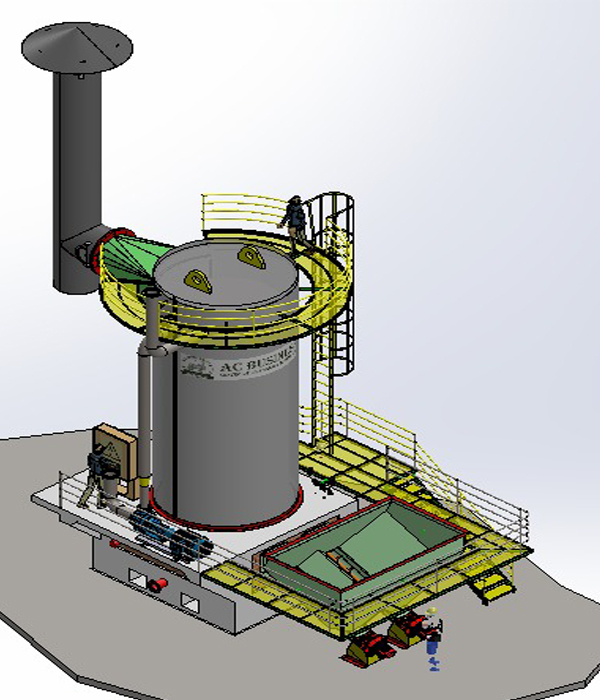

Thermal fluid heater

Used in industrial process requiring high temperature. It consists of a serpentine combustion chamber, through which the oil to be heated circulates, through combustion gases. The system operates at a temperature of up to 300ºC with mineral oil and mineral oil and 380ºC with synthetic oil, pressurized with inert gas.

Specifications

The temperature, speed and oil level parameters in the system are controlled to avoid oil cracking and consequent system collapse. The heater is designed considering thermal oil specification, fuel type and combustion characteristics.

Our models taken into account are:

Mazarote

Biomass

Quesil

Oil & Gas

Quima

Firewood

Oil, Gas, Biomass and Firewood thermal fluid heater. Vertical or horizontal configuration

Double coil system. Removable top cover to allow access for inspection and cleaning of the coils. Low pressure loss of thermal fluid

Three gas pass configuration. Effective thermal insulation

Manufactured with membrane walls using special machines using the

continuous submerged arc welding. This process ensures a complete fusion of the membranes with the pipes, avoiding

cracks caused by expansion differentials.

Constructive design resulting in hermetically sealed equipment preventing phase leakage and the entry of false air..

Grill integrated into the oil circuits of the heater itself, promoting cooling of the heater. Easy to clean grill.

Furnace with membraned walls throughout its length, without the application of refractories. Crushed biomass feeding system throughout the grate extension of the grate ensuring excellent burning.

Rectangular design, a condition that facilitates cleaning at the end of the vertical flow of gases, allowing easy access to all four sides of the heater, thus eliminating the need for equipment stops.

Air preheater, where the combustion air is preheated before being injected into the grate increasing thermal efficiency.

Constructive design resulting in hermetically sealed equipment preventing phase leakage and the entry of false air..

Grill integrated into the oil circuits of the heater itself, promoting cooling of the heater. Easy to clean grill.

Furnace with membraned walls throughout its length, without the application of refractories. Crushed biomass feeding system throughout the grate extension of the grate ensuring excellent burning.

Rectangular design, a condition that facilitates cleaning at the end of the vertical flow of gases, allowing easy access to all four sides of the heater, thus eliminating the need for equipment stops.

Air preheater, where the combustion air is preheated before being injected into the grate increasing thermal efficiency.

The movable grate allows the burning of fuels with high moisture content. Adequate furnace volume

provides a low gas velocity, significantly reducing the entrainment of particulate matter

into the atmosphere. Its vertical construction increases the residence time of the gases in the combustion area,

significantly increasing the burning efficiency. The thermal fluid heater is built on a metal chassis, avoiding costly civil

metal chassis, avoiding costly civil works. The grill is mobile and suspended, with a lower maintenance rate.

CO2 content 14 %

CO content: below 400 PPM

Noise level less than 85 dB at two meters from the source

Biomass-based fuels, liquid, gaseous and powder fuels in a single installation

CO content: below 400 PPM

Noise level less than 85 dB at two meters from the source

Biomass-based fuels, liquid, gaseous and powder fuels in a single installation